All-Optical Sensors

|

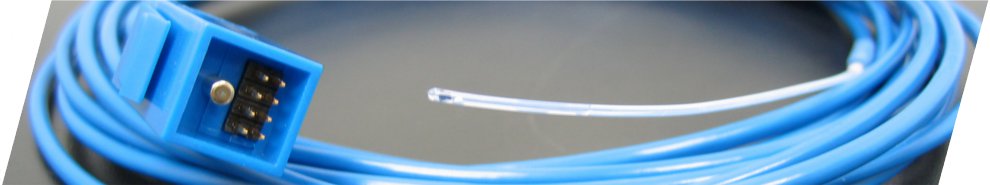

Medical/HealthcareIPITEK's X5 fiber-optic sensor's immunity to RF, and chemically inert materials make them ideally suited for healthcare applications. They can be left in place to monitor patient temperature during CT or MRI scans, or in minimally invasive surgeries that use radio frequencies or microwaves. With the X5-True Sensor and the embedded LumiSmart connector, accuracy can get down under ±0.2 °C without the need for on-site calibration. Typical Medical/Healthcare applications of X5 sensors:

|

|

Sparkproof and Intrinsically Safe Sensing SolutionsEnvironments where volatile and flammable substances can be present generally requires the use of intrinsically safe equipment. IPITEK's line of X5 sensors is ideal for monitoring temperature in this type of environment. Made entirely of dielectric material, our line of Standard and Custom sensors can accommodate a large variety of applications, from monitoring of fuel line temperatures, thermal management in storage of volatile substances to explosive material. Fiber optic sensors are the best way to conform to the most stringent safety regulations. |

|

Adverse and Corrosive EnvironmentsThe X5 system features an environmentally inert, nonconductive, nonmetallic, miniature probe, making it ideal for harsh operating conditions and other applications where metal probes are useless. Since the probe itself is inert to chemical and biological agents, it is ideally suited to applications where a completely non-reactive sensor is required or where other types of sensors would malfunction or become damaged. |

|

Pump and Pipeline MonitoringThermal conditions of mechanical assemblies can tell you a lot on their integrity. X5 fiber optic temperature sensors can measure wide ranges of temperature while remaining accurate and safe in conditions frequently encountered in Oil, Gas, and Mining industries. |

|

Propulsion Testing and Combustion ZonesIn addition to being intrinsically safe and spark proof, fiber optic sensors do not generate heat and are environmentally inert. IPITEK sensors can monitor the temperature of a structure at critical locations while propellant is being consumed. The X5 line of contact sensors or the LT-2000 line of non-contact sensors are selected depending on requirements of the application. |

|

High RF FieldsThe X5 sensor's dielectric construction and immunity to electric and magnetic fields makes them ideal for applications where high fields DC, RF, and microwave fields or high voltages, are present. Such conditions are present in proximity to transmission antennas, high power lines and in electrically-noisy environments. The X5 sensor is EMI immune, and is ideal for temperature hot-spot monitoring in electric power transformers. |

|

Materials ProcessingLT-2000 non-contact temperature sensors are ideal for many high-temperature, plasma, RF, microwave, or volatile material processing applications. IPITEK has also developed a wide range of solutions for precision processing applications such as semiconductor fabrication. |

Application Example

Our sensor transducers and their associated data links form a module. IPITEK integrates these modules with other telemetry and networking equipment, such as video surveillance, into an overall communications system deployment for extreme environments. This graphic illustrates our sensor module concept, and an application scenario follows.

One of the world's largest base metals mines, operating in extremely harsh environments in Latin America, has long used our networking equipment and IMTRAN products for surveillance in its massive underground mining and above-ground processing and control stations. Mine officials use the broadcast-quality video from the drilling machines to remotely control digging from the safety of the surface. This is an ideal environment for integrating IPITEK sensors.